Aluminium Alloy Frame

Plate Freezer Block Frozen Aluminium Alloy Frames (16.5lb/7.5kg)

- 16.5lb/7.5kg Freezing Frames

- Block Frozen Fish Seafood Frames

- Block Pan for Freezing Fish

- Frozen Fish/Shrimp Pans/Trays

- Product description: 16.5lb/7.5kg Plate Freezer Block Frozen Frames

16.5lb/7.5kg Aluminium Plate Freezer Frames

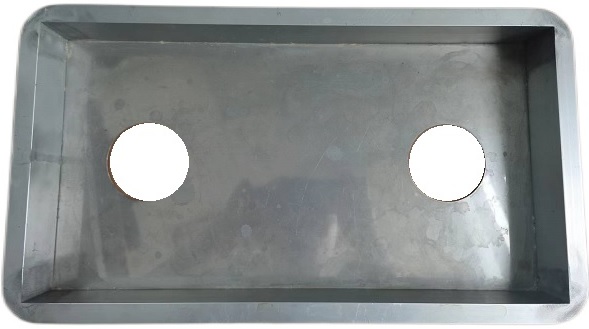

Block Pan (square) for Frozen Fish / Seafood

Dimensions: 485*255*59mm (Inner dimension, standard)

Material: Aluminium alloy / Stainless Steel

Usage: Matching for plate freezer, making frozen fish/meat blocks

Market: Asia Pacific/ North South America / EU / Russia / Africa

Above pictures is one slot frame and two slots fixed bottom freezer frames.

One slot frame out dimension: 525*295*60mm (L*W*H)

Two slots frame out dimension: 1018*295*60mm (L*W*H)

Some European customer use "Bo Anderson Frame" to name them. Freezing Frames may be single slot or double slots, with attached or loose bottoms, in stainless steel or aluminium, or a combination of both. It is important that frames are clean, square and flat. If they are not flat the freezer plates will create uneven pressures on the blocks and other frames. The holes in the bottom plate is for injectors to push the blocks out when freezing is over.

From the top-down they are the "U", the "E" and the "XU" (frame wall structure).

Mainly we can offer "E" style.

We can also provide 1kg, 2kg, 5kg, 10kg freezing pans, trays for frozen H/G, fish blocks, shrimps in plate freezer or shelf freezing in quick-freezing room.

For more info you can kindly check:

https://americanhistory.si.edu/collections/nmah_1330210

The most common and least damaging method of removing the frozen block from the frames is with a pneumatic or hydraulic ejector. An ejector uses metal pistons to push the block out of the frame (through holes in the bottom plate if one is attached).

If the block is too cold during storage it will result in very brittle and easily damaged block. At -30°C the block will maintain its protein quality but can be easily damaged if mishandling occurs. So hammers can not be used to remove the blocks which will crack the frame.

On the left, is the hydraulic ejector which uses electric power, like in China, AC 220V/60Hz. On the right, is the pneumatic ejector, which need compressed air as power supply, meanwhile more clean and cost saving. We can supply above both machines.

Categories

Latest News

Contact Us

Contact: Yang Lee

Phone: +86 18765203281

Tel: +86 18765203281

Add: No.435, Lanzhou East Road, Jiaozhou, Qingdao, China 266000